Product Introduction

This 3 MVA oil immersed transformer was delivered to Greece in 2023 via a Greece trade company, the rated power of the transformer is 3000 KVA, the primary voltage and secondary voltage of the transformer 6.6/0.525kV, The no-load loss of the transformer is required to meet the Tier2 energy efficiency standard, so the loss is very low. The 3 MVA power transformer was designed with advanced technology and adopts high quality material and components which result in reliable quality and long operation time.

SCOTECH ensure each one of our delivered transformers had passed the full acceptance test and we remains 0 fault rate record for more than 10 years so far, our oil immersed power transformer is designed in accordance with IEC, ANSI and other major international standards.

Scope of Supply

Product: Oil Immersed Power Transformer

Rated Power: Up to 200 MVA

Primary Voltage: Up to 230 KV

Technical Specification

3 MVA power transformer specification and data sheet

| Delivered to | Greece |

| Year | 2023 |

| Model | S-M-3000-6.6 |

| Type | Oil Immersed Power Transformer |

| Standard | IEC60076 |

| Rated Power | 3 MVA |

| Frequency | 50 HZ |

| Phase | Three |

| Cooling Type | ONAN |

| Primary Voltage | 6.6 KV |

| Secondary Voltage | 0.525 KV |

| Winding Material | Copper |

| Vector Group | Dyn5 |

| Impedance | 5.8% |

| Tap Changer | NLTC |

| Tapping Range | ±2*2.5% @ Primary Side |

| No Load Loss | ≤1.9 KW |

| On Load Loss | ≤22 KW |

| Accessories | Standard Configuration |

| Remarks | N/A |

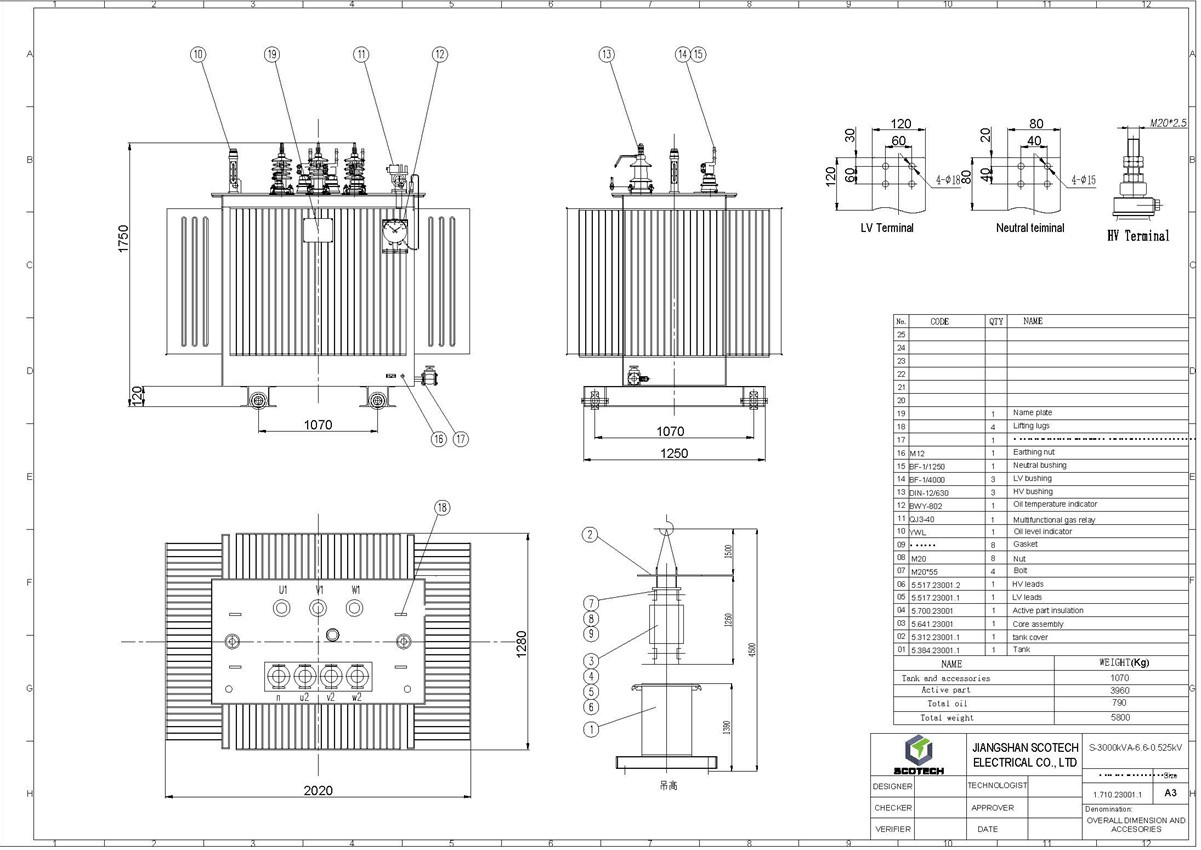

General Arrangement Drawing

3000 kVA power transformer dimensions and weight details

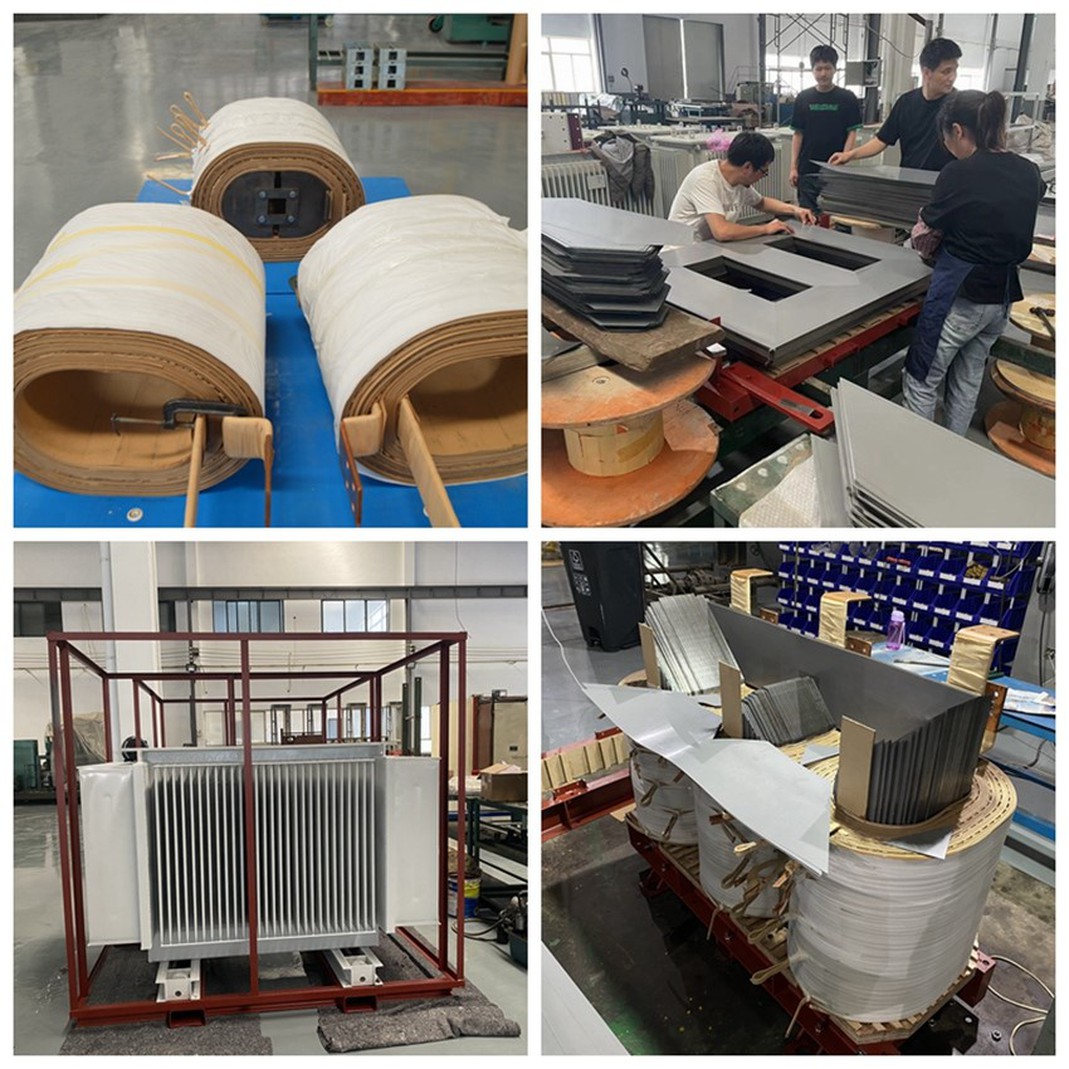

3 MVA-6.6/0.525 kV Transformer Manufacturing

Finished 3MVA 6.6/0.525KV Transformer

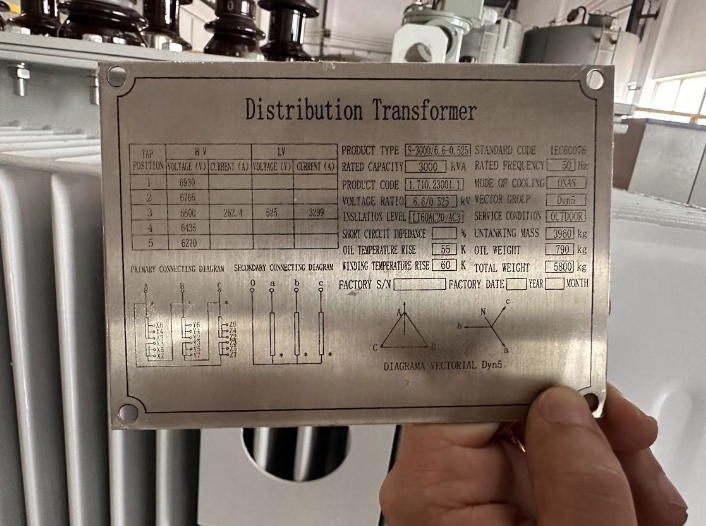

Name Plate

3 MVA Distribution transformer nameplate details

3 MVA 6.6/0.525KV Transformer Testing

Packing and Delivery

How to Reduce Transformer Losses

Transformers are widely used in electric power systems to transfer electrical energy from one circuit to another. However, due to various factors such as resistance, eddy currents, and hysteresis, they can experience energy losses, which decrease their efficiency and increase operating costs. In order to optimize transformer performance, it is critical to understand how these losses can be minimized. In this blog, we will discuss some strategies for reducing transformer losses.

1. Choose the right core material

Using the right core material can greatly reduce transformer losses. Transformer cores are made from magnetic materials such as iron or steel, which can be laminated to reduce eddy currents. High-quality cores that are designed for low loss can improve transformer efficiency.

2. Optimize the winding design

The winding design is another factor that can affect transformer losses. A proper winding design with the right number of turns, correct wire gauge, and uniform winding distribution can minimize losses due to resistance. This can be achieved through careful analysis and simulation of the transformer design.

3. Use high-quality insulation

The insulating material used in the transformer plays a critical role in reducing losses due to hysteresis and eddy currents. High-quality insulating materials such as mica and varnish can provide better insulation and reduce energy losses.

4. Maintain proper cooling

Transformers generate a lot of heat during operation, and overheating can increase energy losses and reduce transformer life. Proper cooling systems such as fans, radiators, or oil-cooling can remove excess heat and ensure efficient operation.

5. Reduce load losses

Load losses occur when the transformer is under load, and can be reduced by improving the power factor, reducing voltage drop, or choosing the right transformer size. Monitoring load losses and optimizing load factors can significantly reduce energy consumption.

In conclusion, transformer losses can be reduced through careful selection of core materials, optimization of winding design, use of high-quality insulation, proper cooling, and load management. By implementing these strategies, transformer efficiency can be improved, resulting in reduced energy consumption, lower operating costs, and increased reliability.

FAQ

1. Where is your main market?

We had exported our transformers to more than 30 countries in the world, our main market is Africa countries, South and North American countries, and Asia countries.

2. What certificate do you have?

We have KEMA, CESI, CTQC type test report for our transformers.

3. How long is your delivery time?

30 days after drawing confirmed by buyer for distribution transformers below 5000kva, bigger transformers depend on the capacity and components, normally 30-90days(with imported components)