Product Introduction

The 6 MVA traction rectifier transformer was delivered to South Africa in 2022 for Transnet’s 3 KV DC traction substations.

Transnet’s traction substations consist of single and double units and in exceptional cases a three unit rectifier configurations.

Each rectifier unit comprises of a set of high voltage AC disconnects, primary circuit breaker, two current transformers and a traction transformer connected for twelve-pulse rectification with its control and protection circuitry.

The rated power of the transformer is 6000 kVA with ONAN cooling, the primary voltage is 22 kV with ±2*2.5% tapping range(NLTC), the secondary voltage is 2 of 1.22 kV, also a tertiary winding is designed to supply a auxiliary 150 KVA 1.22 KV power, they formed a vector group of Y/d11y0y0n.

Our 6 MVA traction rectifier transformer was designed with advanced technology and adopts high quality material and components which result in reliable quality and long operation time.

We ensure that each one of our delivered units has undergone rigorous full acceptance testing. We provide one-package service from consulting, quoting, manufacturing, installation, commissioning, training to after sale services, our products are now operating in more than 50 counties in the world. We aim to be your most reliable supplier as well as your best partner in business!

Scope of Supply

Product: Oil Immersed Rectifier Transformer

Rated Power: Up to 100 MVA

Primary Voltage: Up to 110 KV

The transformer can be designed according to customer’s requirements

Technical Data Sheet

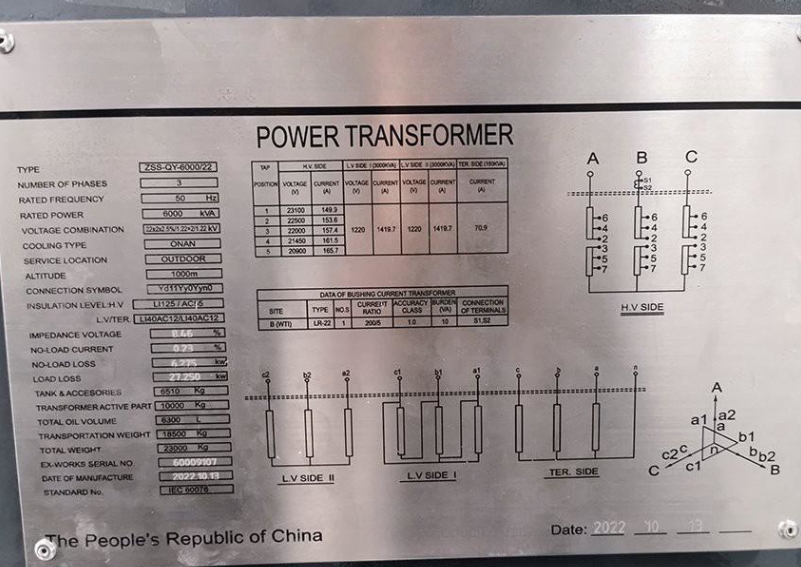

6 MVA oil immersed rectifier transformer specifications and data sheet

| Delivered to | South Africa |

| Year | 2022 |

| Model | ZSS-QY-6MVA-22/2*1.22+1.22KV |

| Type | Oil Immersed Rectifier Transformer |

| Standard | IEC60076 |

| Rated Power | 6 MVA |

| Frequency | 50 HZ |

| Phase | Three |

| Cooling Type | ONAN |

| Primary Voltage | 22 KV |

| Secondary Voltage | 2*1.22+1.22KV |

| Winding Material | Copper |

| Vector Group | Y/d11y0y0n |

| Impedance | ≥8 % |

| Tap Changer | NLTC |

| Tapping Range | ±2*2.5%@ primary |

| No Load Loss | 7800W |

| On Load Loss | 33000W |

6 MVA-22/2*1.22+1.22kV Transformer Drawing

6000 KVA rectifier transformer diagram drawing and size.

6 MVA-22/2*1.22+1.22kV Transformer Manufacturing Process

Transformer Construction of the Core:

In general, the name associated with the transformer structure depends on how the primary and secondary windings are wound on the center laminated steel core. The two most common and basic designs of transformer structure are closed core transformer and shell core transformer.

Winding:

1.Our windings are made of high quality copper.

2.Both High Voltage (HV) and Low Voltage (LV) windings are done using Coil Winding Machines. The Copper strips/wires used in winding are meticulously selected for its quality to give the best output. The Copper strips/wires are paper covered and acts as insulators.

6 MVA Transformer Oil Tank

Final Assembly:

The wound coils are placed carefully in the assembled core. Insulations are given wherever required using materials like press board. The CORE bolt and tie rods are fixed in position. The Primary and Secondary windings are connected as per the requirement.

Finished 6 MVA Rectifier Transformer

6 MVA-22/2*1.22+1.22kV Transformer Name Plate

Customer was doing FAT in Our Factory

Packing and Delivery

Packing attention

Special attention shall be paid to the loading of the transformer when loading: due to the concentrated weight of the transformer, the concentrated load at the bottom of the ship shall be guaranteed when considering the barge to be carried, and reinforcement measures shall be taken if necessary; the bumping wave of the ship shall be taken into consideration in water transportation, and the binding must be firm.

Working Of A Rectifier Transformer

A transformer consisting of two diodes or thyristors is installed in the same tank to regulate the voltage. It is designed to combat eddy current and harmonic problems. It is possible to achieve fine level voltage regulation, and the device is called rectifier transformer, where the regulating unit can be built internally or separately. The device is suitable for high voltage applications.

Many applications require special industrial transformers because existing equipment cannot withstand the load of such applications. It provides the necessary power for the low-voltage power supply and will not cause any problems or damage. They are used in different applications, such as mining, electric furnace, laboratory experiments, variable speed drive motor control, etc.

FAQ

1. Where is your main market?

We had exported our transformers to more than 50 countries in the world, our main market is Africa countries, South and North American countries, and Asia countries.

2. What certificate do you have?

We have KEMA, CESI, CTQC type test report for our transformers.

3. How long is your delivery time?

30 days after drawing confirmed by buyer for distribution transformers below 5000kva, bigger transformers depend on the capacity and components, normally 30-90days(with imported components)