Why Choose a Dry-Type Transformer?

Transformers are vital components in power supply and electrical systems, and they come in various types depending on their insulation methods. Among these, dry type transformers have gained significant attention due to their unique advantages. Unlike oil-immersed transformers, dry-type transformers do not rely on insulating liquids, making them more environmentally friendly and easier to maintain. But what exactly is a dry-type transformer, and why should you choose one?

Do you know enough about dry-type transformers?

In this article, we’ll explore what dry-type transformers are, their various types, advantages, applications, and more.

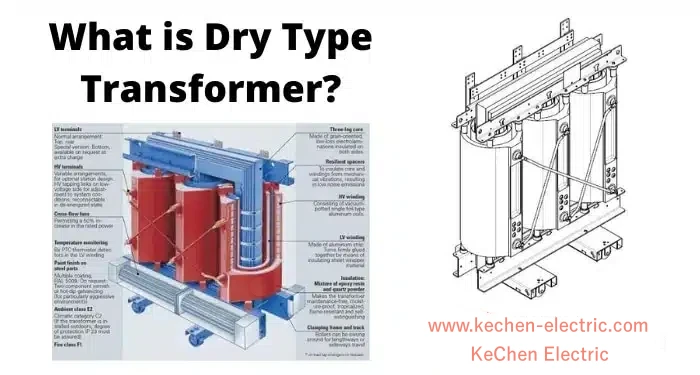

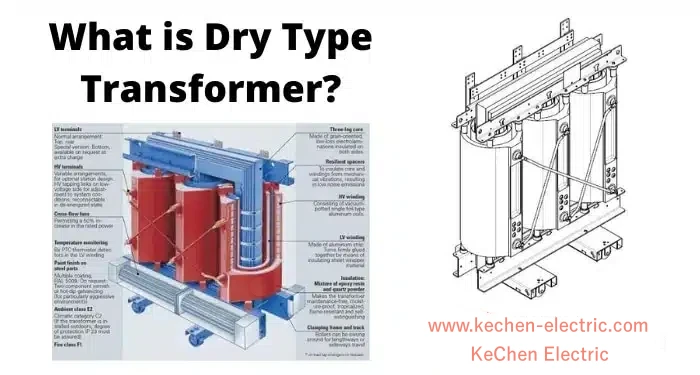

1. What Is a Dry Type Transformer?

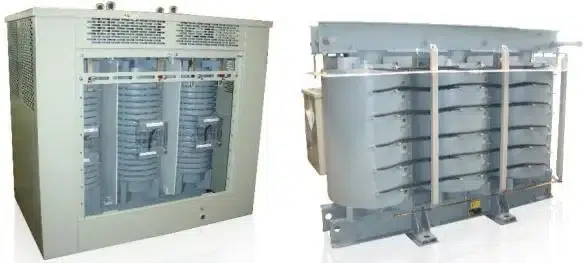

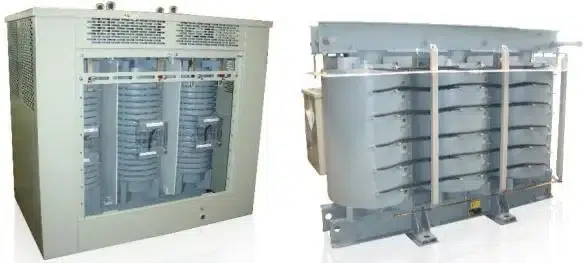

A dry type transformer is a transformer that does not use any insulating liquid. Its windings and iron cores are either exposed to the outside or enclosed in protective shells.

Dry type transformers are also more environmentally friendly than oil-immersed transformers because they use less energy and produce less waste oil. Dry type transformers, often referred to as step-up or step-down transformers, work by converting electrical energy from one voltage level to another, either increasing or decreasing the voltage as needed. Due to their design, they are particularly well-suited for use in areas where fire risk and environmental concerns are a priority.

Dry type transformers are also more environmentally friendly than oil-immersed transformers because they use less energy and produce less waste oil. Dry type transformers, often referred to as step-up or step-down transformers, work by converting electrical energy from one voltage level to another, either increasing or decreasing the voltage as needed. Due to their design, they are particularly well-suited for use in areas where fire risk and environmental concerns are a priority.

2. Types of Dry-Type Transformers

Dry-type transformers come in various forms, designed for different applications. Generally, they fall into two categories: control transformers and power transformers.

2.1 Dry-Type Control Transformer (Industrial)

The dry-type control transformer is a smaller transformer typically used in low-voltage circuits (up to 1,000V), and is designed for continuous operation under rated load. Commonly used in machine tools and mechanical equipment, it provides control power for lighting and electrical appliances.

Typical Applications:

- Control lighting and indicators

- Voltage conversions (e.g., 380V to 220V, 380V to 36V, etc.)

Features:

- Compact size

- Cost-effective

- Strong mobility

- Enhanced heat dissipation

- Lower losses

- Greater security

Rated power ranges from 1KVA to 500KVA, with autotransformer and isolation transformer types available.

2.2 Epoxy Resin Cast Dry-Type Transformer

Epoxy resin cast dry-type transformers are designed as a replacement for oil-immersed transformers. They offer superior performance and reliability. The high-voltage windings are made of copper wire, while the low-voltage windings use either copper wire or foil, impregnated with epoxy resin and cured to form a solid cylindrical body.

These transformers are available in ratings from 25 KVA to 12,500 KVA, with an insulation class of F (90°C temperature rise).

Features:

- Excellent overload capability

- Low partial discharge and reduced losses, ensuring high efficiency

- Fire-resistant winding insulation, ideal for indoor installations

- Hygienic and resistant to moisture

- Can be housed in IP45 enclosures for outdoor use

2.3 Vacuum Pressure Impregnated Transformer (VPI)

Vacuum pressure impregnated transformers feature minimal flammable materials in the insulation, and the windings are made of continuous layers of foil or strip. The winding insulation is impregnated under vacuum with polyester resin, ensuring void-free insulation. These transformers are well-protected against moisture and offer enhanced mechanical strength.

Available in power ratings from 5KVA to 30MVA with insulation grades of F (155°C) and H (180°C), these transformers can be enclosed in protective boxes rated up to IP56.

Features:

- High mechanical strength

- Void-free insulation for improved reliability

- Stable temperature performance

- Fire-resistant design

- Easy maintenance

3. What Are the Benefits of Dry-Type Transformers?

Dry-type transformers offer several advantages over oil-immersed transformers, making them an excellent choice for various industrial and commercial applications:

- Cost-Effective: Dry-type transformers tend to be less expensive than oil-based transformers due to their simpler construction and lower maintenance costs.

- Enhanced Reliability: Dry-type transformers are less likely to overheat and fail compared to oil-immersed transformers, making them more reliable in high-demand environments.

- Environmentally Friendly: Without the need for oil, dry-type transformers are more eco-friendly and pose fewer environmental risks in case of leaks.

- Lower Maintenance Costs: Since they do not require oil monitoring or replacement, dry-type transformers typically have lower maintenance costs over their lifespan.Oil has been known to leak from old oil

- Higher Power Handling: These transformers can handle higher power ratings and voltages, making them suitable for more demanding applications.

- Safer Operation: The lack of oil reduces the risk of fire, making dry-type transformers ideal for use in environments where safety is a critical concern.

4. Applications of Dry-Type Transformers

Dry-type transformers are widely used in various industries and sectors where safety, reliability, and environmental considerations are paramount. Common applications include:

- Industrial Control Systems

- Mechanical Equipment

- Chemical, Oil, and Gas Industries

- Environmental Sensitive Areas (e.g., water reserves, forests)

- Fire risk areas (e.g. forests)

- Urban Substations

- Indoor and Underground Substations

Dry type transformers are also more environmentally friendly than oil-immersed transformers because they use less energy and produce less waste oil. Dry type transformers, often referred to as step-up or step-down transformers, work by converting electrical energy from one voltage level to another, either increasing or decreasing the voltage as needed. Due to their design, they are particularly well-suited for use in areas where fire risk and environmental concerns are a priority.

Dry type transformers are also more environmentally friendly than oil-immersed transformers because they use less energy and produce less waste oil. Dry type transformers, often referred to as step-up or step-down transformers, work by converting electrical energy from one voltage level to another, either increasing or decreasing the voltage as needed. Due to their design, they are particularly well-suited for use in areas where fire risk and environmental concerns are a priority.