Product Video

Product Introduction

This 76 MVA power transformer was delivered to Sichuan,China in 2021, it’s a step down transformer 110 kV to 35 kV, the primary voltage is 110 kV, the secondary voltage is 35 kV, the transformer is equipped with on load tap changer, the tapping range is ±8*1.25% at primary side, the cooling is ONAF. The vector group of this transformer is YNd11,which neutral bushing is in primary side. Current transformer with protection for neutral bushing.The material for HV and neutral bushing is OIP. our 76 MVA power transformer was designed with advanced technology and adopts high quality material and components which result in reliable quality and long operation time.

We ensure that each one of our delivered units has undergone rigorous full acceptance testing. We provide one-package service from consulting, quoting, manufacturing, installation, commissioning, training to after sale services, our products are now operating in more than 50 counties in the world. We aim to be your most reliable supplier as well as your best partner in business!

Scope of Supply

Product: Liquid Filled Power Transformer

Rated Power: Up to 200 MVA

Primary Voltage: Up to 230 KV

The transformer can be designed according to customer’s requirements

Technical Data Sheet

80 MVA oil type power transformer specifications and data sheet

| Delivered to | Sichuan,China |

| Year | 2021 |

| Model | SZ11-76 MVA-110/35 kV |

| Type | Oil Immersed Power Transformer |

| Standard | IEC60076 |

| Rated Power | 76 MVA |

| Frequency | 50 Hz |

| Phase | Three |

| Cooling Type | ONAF |

| Primary Voltage | 110 kV |

| Secondary Voltage | 35 kV |

| Winding Material | Copper |

| Vector Group | YNd11 |

| Impedance | 12 |

| Tap Changer | OLTC |

| Tapping Range | ±8*1.25% |

| No Load Loss | 45 |

| On Load Loss | 299 |

| Accessories | Standard Configuration |

| Remarks | N/A |

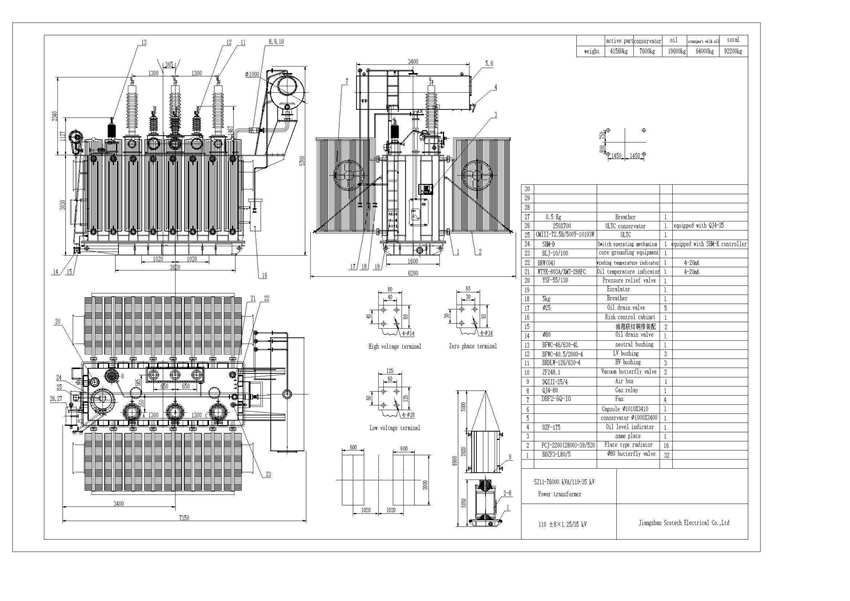

76 MVA 110/35 kV Transformer Drawing

76 MVA power transformer diagram drawing and size.

76 MVA 110/35 kV Transformer Core Manufacturing Process

Transformer Construction of the Core:

In general, the name associated with the transformer structure depends on how the primary and secondary windings are wound on the center laminated steel core. The two most common and basic designs of transformer structure are closed core transformer and shell core transformer.

In the “closed core” type (core type) transformer, the primary and secondary windings are wound outside the core ring. In a “shell” (shell) transformer, the primary and secondary windings pass through a steel magnetic circuit (core), which forms a shell around the windings, as shown below.

Transformer Manufacturing Process – Final Assembly

Final Assembly

The final assembly begins with the removal of the core and coil assembly from the vapor phase. All internal components are re pressed under the pressure specified by the project, and now the excess water has been removed to ensure the tightness. The metal and fiber nuts are tightened or tightened as required, and the electrical clearance is verified again.

The core and coil assembly are placed in the tank, which is filled with oil to prevent exposure to air, and a cover assembly is added to connect with the sleeve. Once the enclosure is welded and leak checked, the galvanized radiator is assembled to the tank, the unit is drained, and the transformer is vacuum filled for final testing. During this period, the control box and any other customer specified monitors and components are installed and connected. All external welded components shall be installed to ensure correct installation to the tank and removed prior to the completion of the factory acceptance test of the transformer.

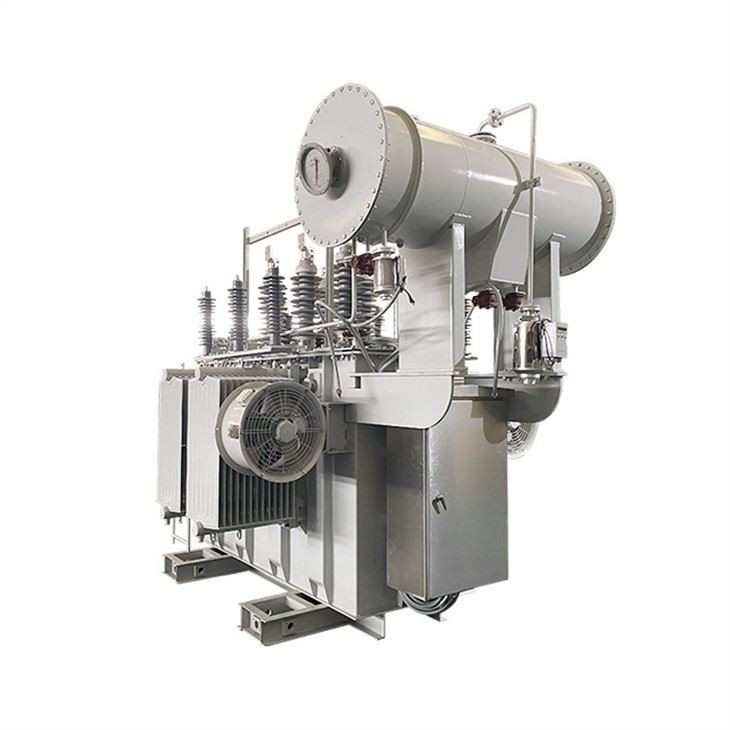

Finished 76 MVA 110/35 kV Transformer

The transformer was painted to gray color (RAL 7035) as customer requirements.

FAQ

1. What is the scope of your supply?

We can supply distribution transformers up to 5000KVA 35KV, power transformers up to 200 MVA 230KV, dry type transformers up to 10 MVA 35KV, and other special transformers such as rectifier transformer and furnace transformers.

2. What service can you provide?

We can provide design, manufacturing, delivery, installation, commissioning, after-sale service.

3. Can I visit your company?

You are welcomed to visit our company at any time, contact us to get start the journey.