There are the following requirements for transformer bushings:

1. It must possess the specified electrical strength and sufficient mechanical durability.

2. It should excellent thermal stability and endure instantaneous overheating during short circuits.

3. Small in compact[small in appearance], small in lightweight[small in quality] , good in sealing performance, strong in versatility, and easy to maintain

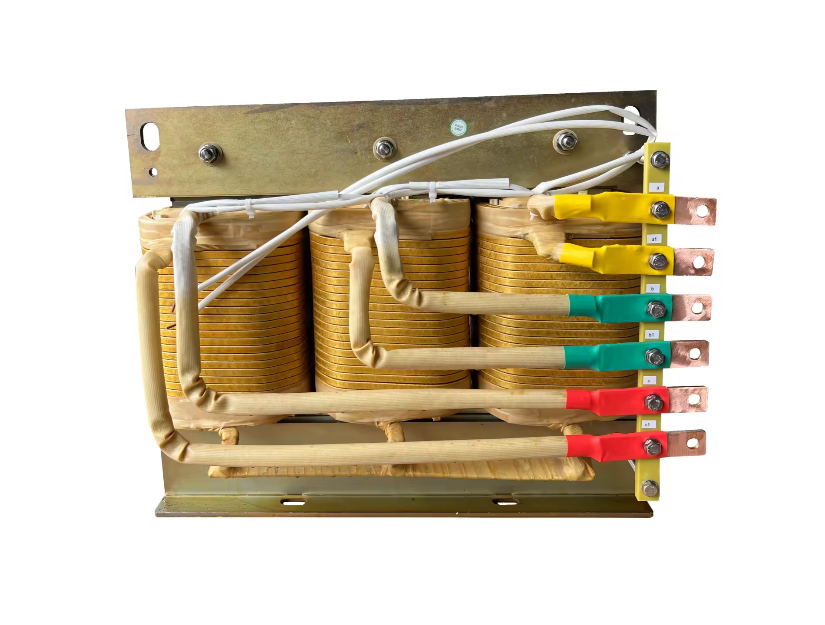

**Structure and Composition**

The bushing primarily consists of a capacitor core, oil conservator, flange, and upper and lower porcelain sleeves. The main insulation is provided by the capacitor core, which comprises concentric capacitors connected in series and enclosed within a sealed container formed by the upper and lower porcelain bushings, oil conservator, flange, and base. The container is filled with processed transformer oil, creating an oil-paper insulation structure.

Oil-resistant rubber gaskets line the contact surfaces between the primary components, ensuring proper sealing. A set of robust springs in the oil conservator applies central clamping force, keeping each component securely sealed. The flange is equipped with essential features such as a vent plug, an oil extraction device, a medium loss measurement tool, and a local discharge monitoring system. The measurement device must be covered during operation to ensure the final screen is grounded, strictly prohibiting open circuits.

There are two connection methods between the bushing and the transformer’s high-voltage lead:

1. Cable threading.

2. Current carrying through a guide rod.

**The Installation Inspection Items**

The inspection items for transformer bushing Before installation, inspect the following:

1. Ensure the surface of the porcelain bushing is free from cracks or scratches.

2. Is the neck of the flange and the inner wall of the pressure equalization ball are clean.

3. whether the casing is qualified after testing

4. Check the oil level indicator on the oil-filled sleeve for normal levels and if there is any oil leakage .

**Usage and Maintenance**

The casing should be used according to its model under its operating specified conditions. and the following precautions should be taken:

Ensuring casing sealing is the key to achieving durability. The sealing structures position during installation or maintenance must be carefully restored to their original sealing state.