1. Basic Concept and Working Principle of Dry-Type Transformers

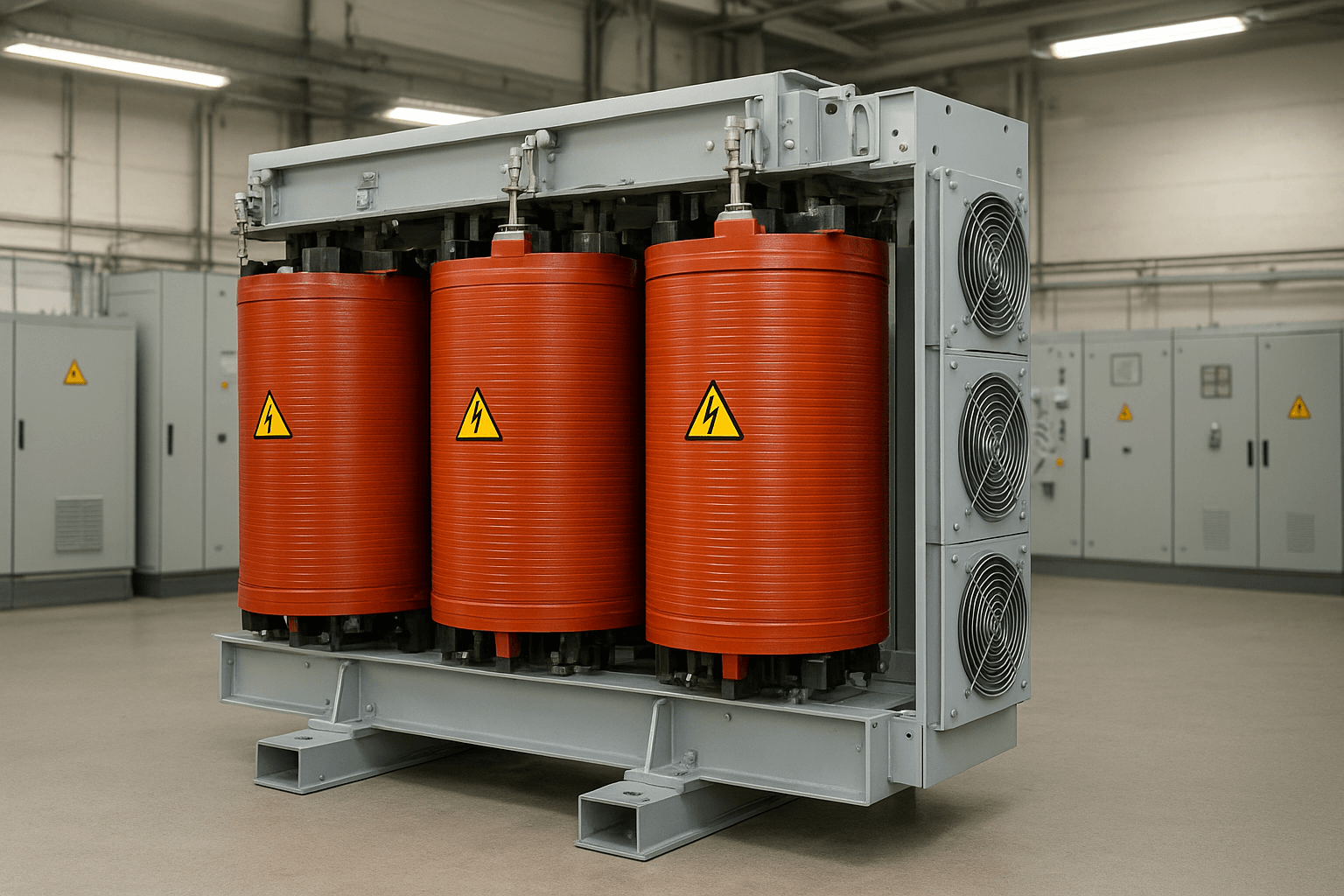

Dry-type transformers are power transformers that do not use liquid insulating media (such as transformer oil). Their windings and cores are either exposed to air or encapsulated with solid insulation materials.

Compared with traditional oil-immersed transformers, they achieve electrical isolation through materials such as epoxy resin or fiberglass, eliminating the risk of oil leakage and fire hazards.

This makes them ideal for locations with strict safety and environmental requirements.

According to insulation methods, they can be categorized as Vacuum Pressure Impregnated (VPI) and Cast Resin Type (CRT).

-

VPI transformers use varnish impregnated into the windings under vacuum and pressure.

-

CRT transformers use epoxy resin cast under vacuum, forming a solid and durable insulation layer.

The working principle still follows Faraday’s Law of Electromagnetic Induction: alternating current in the primary winding induces a magnetic flux in the core, which generates voltage in the secondary winding.

🟩 Modern designs feature optimized magnetic field distribution, reduced eddy current losses, and improved overall efficiency.

2. Core Structure and Material Innovations

A dry-type transformer mainly consists of four key components: core, winding, insulation system, and cooling system — each carefully designed to ensure reliability, performance, and efficiency.

(1) Core Structure

The core is typically made of cold-rolled silicon steel sheets or amorphous alloy materials with high magnetic permeability.

🟦 Amorphous alloy cores can reduce no-load losses by more than 30%, making them especially suitable for variable load applications.

(2) Winding System

Windings are constructed from copper or aluminum conductors.

🟦 Copper provides higher conductivity and mechanical strength, while aluminum offers cost and weight advantages.

🟩 Advanced foil-wound and multi-layer designs help minimize eddy current loss and enhance thermal performance.

(3) Insulation System

The two main insulation types are epoxy resin cast and VPI insulation, both offering excellent resistance to moisture, dust, and electrical stress.

(4) Cooling System

Dry-type transformers primarily use natural air cooling (AN) or forced air cooling (AF).

🟩 For high-capacity units, a hybrid AN/AF system ensures stable temperature rise under heavy loads.

3. Performance Features and Technical Advantages

🟩 Dry-type transformers combine safety, sustainability, and smart functionality, delivering outstanding operational reliability.

-

High Safety: No oil means no fire or explosion risk — ideal for high-rise buildings, underground facilities, and offshore platforms.

-

Environmentally Friendly: No oil leakage or PCB pollution; low noise operation (≤50 dB).

-

High Efficiency: 15%–30% lower losses than conventional oil-immersed types.

-

Low Maintenance: No oil checks, filters, or gasket replacements — truly maintenance-free.

-

Strong Adaptability: Operates reliably in high humidity, high altitude, and corrosive conditions.

-

Smart Monitoring: Supports IoT-based monitoring for temperature, humidity, and partial discharge detection.

4. Diverse Application Fields

(1) Power Systems

🟦 Extensively used in urban and rural grids, indoor substations, and smart grid networks for safe and compact power distribution.

(2) Industrial Applications

🟩 Ideal for petrochemical, metallurgical, and mining operations where explosion-proof and corrosion-resistant performance is required.

(3) Renewable Energy

Widely deployed in wind farms and solar power plants for voltage transformation and grid connection.

(4) Data Centers and Telecommunications

🟦 Quiet, compact, and safe — perfectly suited for data centers and 5G base stations.

(5) Transportation and Urban Infrastructure

Commonly used in railways, subways, EV charging stations, and public utilities.

Conclusion

🟩 As the world moves toward safer and more sustainable power infrastructure, dry-type transformers are driving the next generation of green and intelligent energy systems.

With continuous innovations in core materials, insulation technology, and smart monitoring, they are steadily replacing oil-immersed transformers in more demanding and diverse applications worldwide.